|

|

|

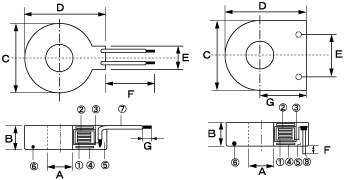

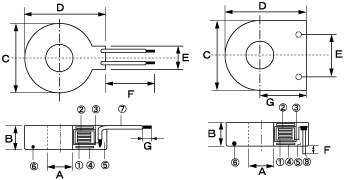

ZCT STANDARD DIMENSION |

| |

| MODEL NO. |

A(Min.) |

B(Max.) |

C(Max.) |

D(Max.) |

E |

F |

G |

RATED CURRENT |

| SH7SP |

6.8 |

6.0 |

17.0 |

18.0 |

10 |

3.0 |

@ |

FOR 30A |

| SH7P |

6.8 |

7.0 |

17.0 |

18.0 |

10 |

2.5 |

@ |

V |

| SH7 |

6.8 |

7.5 |

17.0 |

19.5 |

6.0 |

70.0 |

3.0 |

30,50A |

| SH9 |

9.0 |

7.6 |

22.0 |

25.0 |

6.0 |

70.0 |

3.0 |

30,50A |

| SH10 |

9.4 |

7.6 |

19.0 |

21.0 |

6.0 |

70.0 |

3.0 |

50,100A |

| SH11 |

10.2 |

9.0 |

24.0 |

27.0 |

6.0 |

70.0 |

3.0 |

V |

| SH12 |

10.3 |

8.7 |

22.0 |

24.0 |

6.0 |

70.0 |

3.0 |

V |

| SH15 |

13.6 |

9.3 |

28.3 |

31.0 |

6.8 |

70.0 |

3.0 |

100,125A |

| SH16 |

15.5 |

9.0 |

30.0 |

33.0 |

6.0 |

70.0 |

3.0 |

100,125A |

|

|

|

MATERIALS |

| |

| No. |

NAME |

MATERIALS |

| 1 |

Core |

Permalloy |

| 2 |

Core case |

iC@P.P resin |

| 3 |

Winding |

2UEW Ó0.08-1.0 |

| 4 |

Shiled

Plate |

Iron |

|

| No. |

NAME |

MATERIALS |

| 5 |

Encapsulati |

Epoxy resin |

| 6 |

Outer case |

UL-94 V-O@iïR«j |

| 7 |

Lead Wire |

Tinned Cu PVC coat |

| 8 |

Lead

pin |

Tinned

Cu Ó08 |

|

|

|

PROPERTIES |

| |

| ITEM. |

Propertu |

Condition |

| Output |

E2 : 17-22mV |

I ; 25mA, f ; 60Hz, OR ; 1K¶ |

| Remainence

magnetism |

à ; 10% Max. |

IDC : 50A OutPut voltage ratio after

magnetized |

| Thermal

property |

ÃÑ ; }10% |

-10`}50 Output voltage ratio |

| Permissible

Unbalance |

Eb

; 10mV Max. |

I

; 180A, R ; 1K¶, 60Hz |

|

|

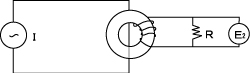

DIAGRAM of PROPERTY TEST |

| |

| 1,Output

(E2) : |

| |

Measured after demagnetization. |

|

|

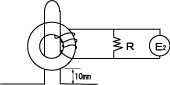

2,Permissible Unbalance (Eb) : |

| |

Peak effective

value measured by turning ZCT round the primary einding

jig. |

|

|

|

|

|

|